Ideal Roof Types for

Roof Coating Application

- Metal Roof Restoration

- Built-up asphalt

- Modified Bitumen Membranes

- Single-ply membranes

- EPDM rubber

- TPO (Thermoplastic Polyolefin)

- Spray Foam

- and more…

What is Liquid Applied Roof Coating?

Elastomeric roof coating is a cutting-edge roofing solution designed to protect and enhance the performance of commercial and industrial roofs. Applied as a liquid directly onto the roof surface, it forms a seamless and resilient protective layer, sealing cracks and gaps to prevent leaks and water intrusion.

With versatile formulations like silicone, acrylic, and polyurethane, each catering to specific roofing needs, liquid applied coatings offer UV resistance, reflectivity, and exceptional durability. This adaptable solution is suitable for various roof types, including flat roofs, metal roofs, and irregular surfaces, providing comprehensive coverage and eliminating the need for costly tear-offs.

By extending the lifespan of existing roofs and reducing waste, liquid applied roof coatings contribute to eco-friendly practices and lower cooling costs, making them a practical and sustainable choice for property owners looking to elevate their roof’s performance and efficiency.

Massive Cost Saving – as low as

Silicone Coating

$1.5

Per Square Foot

VS

Traditional Roof

$6-8

Per Square Foot

industry-leading warranty

Material

50

YEARS

AND

Labor

20

YEARS

Benefits of Roof Coating

Seamless

Protection

Liquid applied coatings create a seamless, watertight barrier, preventing leaks and water intrusion.

highly

Adaptable

Liquid applied coatings work on flat roofs, metal roofs, and irregular surfaces, ensuring comprehensive coverage for diverse roofing structures.

Time & Cost

Savings

Application over existing roofs eliminates tear-offs and disposal fees, saving time and money on roof replacements

Versatile Formulations

Various coatings such as silicone, acrylic, and polyurethane cater to specific roofing needs, offering UV resistance, reflectivity, and durability.

Eco-Friendly

Solution

Reflective coatings lower rooftop temperatures, reducing cooling costs and supporting sustainable building practices.

Extended Roof Lifespan

The protective layer extends the life of the roof, increasing its longevity and reducing the need for frequent repairs.

how we do it

Roof Coating

Application Process

The commercial roof replacement landscape has evolved with the advent of advanced coating technologies like elastomeric coating. This specific process is designed to give buildings a renewed lease on life.

The journey to applying this cutting-edge elastomeric coating begins with an exhaustive surface preparation. This step is pivotal, ensuring that the roof is not only clean but also smooth, devoid of any debris or residues that might hinder the coating process.

Upon preparing the surface, a specially-formulated primer is applied, acting as a bridge to promote an unbreakable bond between the elastomeric coating and the existing roof material. Experienced roofers, equipped with knowledge and precision, then administer the liquid coating. This is not just any layer; it forms a unified, seamless shield that dives deep into cracks, gaps, and minor imperfections, essentially erasing them. As a crucial checkpoint, meticulous quality inspections are conducted post-application.

These assessments guarantee a flawless and even spread of the coating, offering commercial and industrial property owners not just an alternative to traditional commercial roof replacement but an upgrade. The result is long-lasting protection, paired with significantly enhanced roof performance and durability.

step-by-step

Select High-Quality Roof Coating Products

Thoroughly Clean the Roof Surface

Address & Repair Any Roof Damage

Waterproof Porous Surfaces

Apply Coating Product: spray, roll, brush or Trowel

Quality Inspection

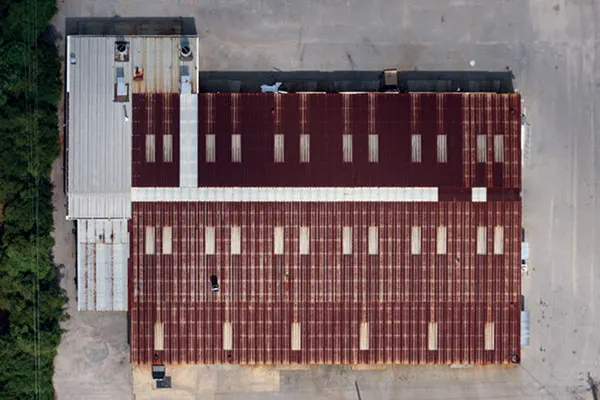

Before and after

Save Up to 40% on Energy Costs with Liquid Applied Roof Coatings

Roof coatings offer significant energy-saving benefits for building owners, with some formulations reflecting up to 40% of solar radiation. This reflection capability is more than just a number. When a roof coating reflects such a significant chunk of solar energy, it directly influences the rooftop’s temperature, making it cooler. In practical terms, this means that the building’s internal temperature remains more stable, requiring less effort from air conditioning systems. The direct consequence? A remarkable reduction in cooling costs.

For building owners, this translates into palpable energy savings, which, when tallied over months and years, can amount to significant financial benefits.This environmentally-friendly solution contributes to a greener and more sustainable building while providing substantial financial advantages over time.